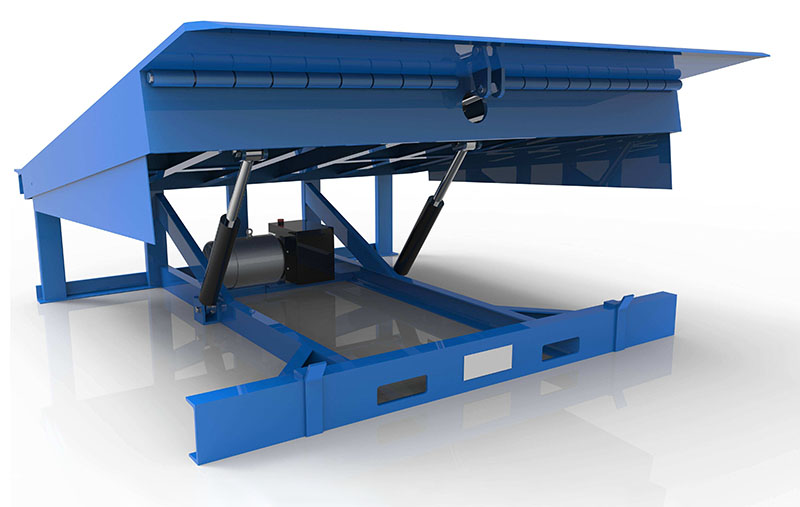

High quality hot sale heavy duty warehouse fixed hydraulic system fixed boarding bridge

Product Description

The advantages of the fixed boarding bridge: electro-hydraulic, simple operation, adjustable height, large adjustment range, improve loading and unloading efficiency, and save manpower.

Its main function is to build a bridge between the cargo platform and the transport vehicle, so that the forklift can travel conveniently to achieve the purpose of loading and unloading. One end of the device is the same height as the cargo bed. The other end is placed on the rear edge of the carriage, and can be changed according to different models and the carriage during the loading process. The height can be adjusted automatically, and the product can be specially designed in terms of load bearing of the outer frame size according to the different needs of users.

DCQG type is an electro-hydraulic boarding bridge, which is mainly used for large-tonnage batch loading such as warehouses and cargo factories with platforms such as post offices, factories, etc. It has the characteristics of safety, reliability and high efficiency.

★ Perfect design, compact hydraulic control mechanism, reliable quality.

★ The hydraulic system manufactured by the introduction of foreign advanced technology has reliable quality.

★ The frame made of rectangular tube has high strength and large bearing capacity.

Features

1. The operation is simple, the rise and fall can be easily controlled only by the control button, and the height of the boarding bridge can be adjusted freely according to the height of different carriages.

2. The I-shaped design structure is adopted, and the overall structure is made of high-quality steel, with strong bearing capacity and not easy to deform.

3. When not in use, the bridge deck and the platform are on the same level, which will not affect other operations.

4. Equipped with power failure emergency braking function, when there is a sudden power failure, the boarding bridge will not drop suddenly, ensuring the safety of personnel and goods.

5. The bridge deck is designed with anti-skid panels, and the anti-skid performance is very good.

6. It is equipped with anti-collision rubber blocks to ensure that the vehicle will not hit the platform and cause damage during the process of contacting the boarding bridge.

7. Release the toe protection board. After the boarding bridge is raised, the protection boards on both sides will automatically expand to prevent the staff from accidentally entering the gap.

Precautions

1. The boarding bridge must be designated for operation and maintenance, and unskilled personnel are not allowed to operate it without authorization.

2. No person shall enter under the boarding bridge frame or on both sides of the safety baffle to perform other operations when the boarding bridge is working, in order to avoid danger!

3. Overload use is strictly prohibited.

4. When the boarding bridge is loading and unloading, it is strictly forbidden to press the operation button.

5. When the slat is straightened, the operation button should be released immediately to prevent the oil cylinder from being under pressure for a long time.

6. In the process of work, if there is any abnormal situation, please remove the fault first and then use it, and do not use it reluctantly.

7. The safety strut must be used correctly during repair or maintenance.

8. During the loading and unloading operation of the boarding bridge, the car must brake and stop steadily.